2000HP SCR Drive

Land rig123.net' target='_blank'>Drilling rig123.net' target='_blank'>Rig

2000HP SCR Drive Land Drilling Rig

-

Model ZJ70/4500D, 2000HP, SCR drive land drilling rig,designed to drill and complete oil and gas wells with a depth below 7000 meters.

-

The rig naming and model coding and basic technical specification conform to China national petroleum industry standards. All key rig components conform to API specifications and API monogram permitted to be stamped

-

The mast is designed in 45 meters high, suitable for installing 500-

ton top drive unit, mast components including monkey board, stabbing board, mast ladders and other mast auxiliary parts. -

The substructure is fabricated with a floor height of 9 meters or 10.5 meters high, attached with ramp, floor man escape kid, steps, and dog houses, etc.

-

The drilling rig is equipped with four diesel generator sets as the rig main mover. And one each 400Kw/50Hz assistant generator, intentionally designed to used while the main generators unused.

-

An SCR drive system and motor control centers (MCC) well fabricated in an air-

conditioned house unit, inside equipped with generator control units, SCR panels, eddy power panel, PLC panel, MCC panels, AC power transformer unit, etc -

Three each 1600HP, 5000psi working pressure, single action, triplex mud pump driven by two each 800Kw, 0-

750Vdc, DC motor. -

The mud pump discharge pipe manifold, including discharge line, standpipe manifold, standpipe, are equipped with the rig package.

-

One each 2000HP drawworks is designed to be driven by two each 800Kw, 750Vdc, DC motor.

-

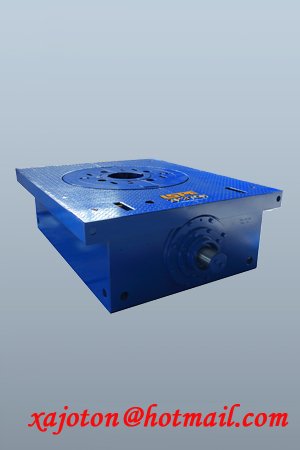

The rotary table is individually driven by a compound drive system consisting of one each 800Kw DC motor, gearbox, and drive shaft.

-

A 6-

pit mud circulation available, including mud tanks, mud mixing system and mud condition system. -

The solids control system consists of shale shaker, degasser, mud cleaner, centrifuge, and polymer shear unit.

-

The drilling instrument system mainly consists of analog and digital drilling data watching and recording equipment. it will monitor and recording WOB, ROP, SPM, Standpipe pressure, rotary torque, mud return, and mud tank level monitors, etc.

-

Well control system, including BOPs, kill and manifolds and BOP control console, will provided up to client's option.

-

Auxiliary rig equipment, such as heavy-

duty warehouses, tool skid, workshops and live camp unit can be furnished with the rig package.

2000HP VFD Drive Land Drilling Rig

-

Model ZJ70/4500DB, 2000HP, VFD drive land drilling rig is designed to drill and complete oil and gas wells with a depth below.

-

The rig naming and model coding and basic technical specification conform to Chinese National Standards. All key rig components conform to API specifications and API monogram permitted to be stamped.

-

The mast is designed in 45 meters high, suitable for installing 500-

ton top drive unit, including monkey board, stabbing board, mast ladders, and other mast auxiliary parts. -

The substructure is fabricated with a floor height of 9 meters or 10.5 meters high, attached with ramp, floor man escape kid, steps, and dog houses, etc.

-

The drilling rig is equipped with four diesel generator sets as the rig main mover, and one each 400Kw/50Hz assistant generator, intentionally designed to used while the main generators left standby

-

An Variable Frequency Drive (VFD) system and motor control centers (MCC) well fabricated in two air-

conditioned house units, inside equipped with generator control units, VFD drive panels, eddy power panel, PLC panel, MCC panels, AC power transformer unit, etc -

Three each 1600HP, 5000psi working pressure, single action, triplex mud pump each driven by two each 800Kw,600Vac AC motor, or one each 1600HP AC motor

-

The mud pump discharge pipe manifold, including discharge line, standpipe manifold, standpipe, are equipped with the rig package.

-

One each 2000HP drawworks is designed to be driven by two each 800Kw, 600Vac, AC motor.

-

The rotary table is individually driven by an 800Kw AC motor and gearbox.

-

A 6-

pit mud circulation available, including mud tanks, mud mixing system and mud condition system. -

The solids control system consists of shale shaker, degasser, mud cleaner, centrifuge, and polymer shearing unit.

-

The drilling instrument system mainly consists of analog and digital drilling data watching and recording equipment. it will monitor and recording WOB, ROP, SPM, Standpipe pressure, rotary torque, mud return, and mud tank level monitors, etc.

-

Well control system, including BOPs, kill and manifolds and BOP control console, will provided up to client's option.

-

Auxiliary rig equipment, such as heavy-

duty warehouses, tool skid, workshops and live camp unit can be furnished with the rig package. -

-

1500HP Electrical Land Drilling Rig

-

Model ZJ50/3150D/DB and ZJ50/3150D/DB, 1500HP, electrical onshore drilling rig, designed to drill and complete an oil and gas well with a depth of not more than 5000m.

-

The rig components such as mast, substructure, traveling block, hook, swivel, rotary table, drawworks, etc, conform to API specifications and the industry standards.

-

The mast fabricated in a pin connection type cantilever structure, monkey board, stabbing board and other mast auxiliaries equipped the mast assembly, its dimensions suitable to install top drive unit.

-

The substructure can be manufactured in two-

step raising and/or box- on- box substructure. And Steps, handrails, BOP handling trays and other appendixes equipment and facilities fully equipped with the substructure. -

The main rig movers are diesel engine driven AC generators with enough power for operating the rig.

-

The power drive system available in SCR (AC-

SCR- DC) or VFD (variable Frequency Drive, AC- DC- AC) system . -

The drawworks electrically driven by heavy duty DC or AC motors, with working speed continuously adjustable. Disc brake introduced as the main drum brake, and an eddy current brake also equipped with the drawworks unit.

-

The mud pumps equipped with the rig are single action, triplex slurry pumps, electrically driven by AC or DC truck motors.

-

Rotary table independently driven by a drive system consisting of truck motor, chain gearbox and universal shaft, with working speed continuously adjustable.

-

Air system equipped with the rig, consisting of two each screw rod type air compressor, air tanks, and valves, and valves.

-

A fully equipped mud circulation system including mud tanks, solids control equipment, mud conditioning equipment and circulation lines completed with the rig package.

-

An analog and digital drilling parameter and data monitor and recording system available on the rig.

-

BOP and well kill/choke equipment and facilities shall be equipment with the rig package according to client's requirement.

-

Water and fuel storage and transfer tanks equipped with the rig package

1500HP Mechanical Land Drilling Rig

-

Model ZJ50/3150L and ZJ50/3150LB, 1500HP, mechanical land drilling rig is used to drill and complete 5000m deep oil, gas and water wells.

-

The drilling rig equipped with three diesels and two mud pumps as the main equipment. The driving mode is that three diesels drive drawworks, mud pumps, rotary table, and catheads through the hydraulic torque converter and the one-

piece chain compound case. The rotary table and the catheads are driven through sloping right angle transfer case and the sloping cardan shaft as well as through above two components. -

The rotary drilling operation condition has the higher drilling speed and torque converting range, the drawworks has also the higher hoisting speed range, and mud circulating system has the higher hydraulic horsepower and pump pressure.

-

The total modularized driving arrangement can satisfy the needs of prompt assembly and disassembly and convenient maintenance, adjustment, inspection and transportation.

-

For the sake of promoting the assembly and disassembly efficiency. The connection between substructure modules is the hasp connection or the end faces positioning bolt connection.

-

Because all driving components, are concentrated according to the arrangement principle of eight modules in the structural design, the truck number required for moving the drilling rig is reduced and the moving speed is improved.

-

The drawworks is installed in a low position, which solves the problem that it is difficult to hoist it onto the raised floor and keep the safety sense, and increases the effective utilization area of the drill floor.

-

To solve the problem that it is difficult to ensure the quality of the chain installation of the open type chain drive case and butt type chain compound case of the existing drilling rigs, which is one of causes of frequently breaking the chain, the integral chain compound case and the integral input chain drive case of drawworks are designed and manufactured by using one-

piece process technique, promoting the installation quality and efficiency. -

7.5m drill floor height and 6.3m clear rotary beam height are favorable to the back flow of the mud into the well, the arrangement of mud tanks and the suction of mud pumps.

-

The mechanized wellhead tools (either the mechanical cathead or the hydraulic cathead) may reduce drilling workers' labor intensity.

1000HP Electrical Land Drilling Rig

-

Model ZJ40/2250D and Model ZJ40/2250DB, 1000HP, electrical land drilling rigs are designed to drill and complete oil and gas wells with a depth of 2500m-

4000m by using 4- 1/2" API drill pipe. The drilling rigs are mainly equipped with 43m high open- front type mast, module mounted substructure with 6m drill floor height and 800mm rear drill floor height, chain- drive transmission system. -

The rig components such as mast, substructure, traveling block, hook, swivel, rotary table, drawworks, etc, conform to API specifications and the industry standards.

-

The mast fabricated in a pin connection type cantilever structure, monkey board, stabbing board and other mast auxiliaries equipped the mast assembly, its dimensions suitable to install top drive unit.

-

The substructure can be manufactured in two-

step raising and/or box- on- box substructure. And Steps, handrails, BOP handling trays and other appendixes equipment and facilities fully equipped with the substructure. -

The main rig movers are diesel engine driven AC generators with enough power for operating the rig. The power drive system available in SCR (AC-

SCR- DC) or VFD (variable Frequency Drive, AC- DC- AC) system . -

The drawworks electrically driven by heavy duty DC or AC motors, with working speed continuously adjustable. Disc brake introduced as the main drum brake, and an eddy current brake also equipped with the drawworks unit.

-

The mud pumps equipped with the rig are single action, triplex slurry pumps, electrically driven by AC or DC truck motors used for the high pressure drilling fluid circulation, complete with mud discharge manifold, standpipe manifold and standpipe.

-

The hoist and traveling system has a nominal load capacity of 2250Kn.

-

A two air compressor source system is available on the rigs, used to power all the air users, such as air hoists, air pumps on BOP pressure control system, air winch on stabbing board.

-

A fully equipped mud circulation system including mud tanks, solids control equipment, mud conditioning equipment and circulation lines completed with the rig package.

-

Rotary table driven by an independent system consisting of chain box and universal shaft, powered by a frequency variable AC motor, or by gearbox and shaft powered by chain compound

-

An analog and digital drilling parameter and data monitor and recording system available on the rig.

-

The electrical applicants and equipment such as AC motors, lights, and switch boards, are explosion-

proof and well protected. -

Drilling instrument system monitor and record drilling operation data, including weight on bit, rotary table speed and torque, well depth, mud pump stroke and pressure, standpipe pressure, mud return volume, liquid level and volume of mud tanks, etc.

-

Water and fuel storage and transfer tanks equipped with the rig package BOP and well kill/choke equipment and facilities shall be equipment with the rig package according to clients requirement.

1000HP Mechanical Land Drilling Rig

-

Model ZJ40/2250L and Model ZJ40/2250LB, 1000HP, mechanical land drilling rigs are designed to drill and complete oil and gas wells with a depth of 2500m-

4000m by using 4- 1/2" API drill pipe. The drilling rigs are mainly equipped with 43m high open- front type mast, module mounted substructure with 6m drill floor height and 800mm rear drill floor height, chain- drive transmission system. -

Two each 1300HP, 5000psi working pressure, mud pump equipped with the rig, used for the high pressure drilling fluid circulation, complete with mud discharge manifold, standpipe manifold and standpipe.

-

Three each model PZ12V190B-

3 diesel engines or equivalent, compete with YB900 torque converter are used to be the main rig power that is transmitted into a chain drive compound box. The compound boxes with three input shafts are designed to drive two 1300HP mud pumps, drawworks, and rotary table. -

The hoist and traveling system has a nominal load capacity of 2250kN that is 250 short tons. The key rig components, such as drawworks, crown block, traveling block, swivel, rotary table, hook, mud pump, high pressure valves, mast, and substructure, conforms to API Specifications.

-

A two air compressor source system is available on the rigs, used to power all the air users, such as air hoists, air pumps on BOP pressure control system, air winch on stabbing board.

-

Mud pump driven by universal shaft through chain compound

-

Rotary table driven by an independent system consisting of chain box and universal shaft, powered by a frequency variable AC motor, or by gearbox and shaft powered by chain compound

-

Drawworks driven through chain compound transmission

-

The electrical applicants and equipment such as AC motors, lights, and switch boards, are explosion-

proof and well protected. -

Drilling instrument system monitor and record drilling operation data, including weight on bit, rotary table speed and torque, well depth, mud pump stroke and pressure, standpipe pressure, mud return volume, liquid level and volume of mud tanks, etc.

750HP Truck Mounted Land Drilling Rig

-

The truck-

mounted land drilling rigs are designed and manufactured in accordance with API Specs Q1, 4F, 7K, and 8C, and National Standards of RP500,and National Standards of GB3826.1, and GB3836.2, GB7258,SY6584. -

The rig packages have compact structure, which requires a small installation space due to its high integration so as to meet the requirements of Heath, safety, and Environment protection.

-

The heavy-

duty and self- propelled chassis: 14x8 and hydraulic steering system are utilized respectively, which ensures the drilling rig a good passage and cross- country capability. -

The reasonable assembly of CATERPILLAR engine and ALLISON transmissions can ensure high driving efficiency and working reliability.

-

The main drum brake adopts hydraulic disc brake or band brake, and air brake or hydraulic brake or FDWS brake can be applied as auxiliary brake.

-

The rotary table transmission box can realize forward-

reverse shift, which can be suitable for all kinds of DP rotary operations, and the anti- torque releasing device can be used to make the DP deformation force released safely. -

The mast, which is front open and double-

section type with an inclination angle or erective double- section type, can be erected or lowered and telescoped hydraulically. -

The drill floor is twin-

body telescopic type or with parallelogram structure, which is convenient for easy hoist and transportation. The height of the drill floor can be designed according to the client's requirements. -

The perfect configurations of solid control system, well control system, high-

pressure manifold system, generator house, engine & mud pump house, doghouse and other auxiliary facilities can meet user’s different requirements. -

AC generator sets can be furnished with the rig packages according to clients requirements.

-

Drilling fluid circulation system can be equipped with the drilling rig packages according to clients requirements, being made up of mud tanks, solids control equipment, mud pump(s), high pressure discharge manifolds.

-

According to clients requirements, other auxiliary equipment and tools can be furnished with the drilling packages.

650HP Truck Mounted Land Drilling Rig

-

The truck-

mounted land drilling rigs are designed and manufactured in accordance with API Specs Q1, 4F, 7K, 8C and RP500,GB3826.1, and Chinese national standards of GB3836.2,GB7258,and SY6584. -

The rig packages have compact structure, which requires a small installation space due to its high integration so as to meet the requirements of Heath, safety, and Environment protection.

-

The rig carrier is equipped with type 12x8 heavy-

duty and self- propelled chassis. -

Driver's cabin and hydraulic steering system are furnished with the carrier, which ensure the carrier have good driving operational ability.

-

Reliable CAT engine and ALLISON transmission is equipped with the rig carrier, used as the main power of the drawworks, rotary table and carrier.

-

The main drum brake adopts hydraulic disc brake or band brake, and air brake or hydraulic brake or FDWS brake can be applied as the auxiliary brake of drawworks.

-

The rotary table transmission box can realize forward and reverse shift, which can be suitable for all kinds of DP rotary operations, and the anti-

torque releasing device can be used to make the DP deformation force released safely. -

The derrick is a two section, telescoped structure, erected by and lower down by hydraulic cylinders

-

The drill floor is twin-

body telescopic type or with parallelogram structure, which is convenient for easy hoist and transportation. The height of the drill floor can be designed according to the client’s requirements. -

The perfect configurations of solid control system, well control system, high-

pressure manifold system, generator house, engine & mud pump house, doghouse and other auxiliary facilities can meet user's different requirements. -

AC generator sets can be furnished with the rig packages according to clients requirements.

-

Drilling fluid circulation system can be equipped with the drilling rig packages according to clients requirements, being made up of mud tanks, solids control equipment, mud pump(s), high pressure discharge manifolds.

-

According to clients requirements, other auxiliary equipment and tools can be furnished with the drilling packages.

Truck Mounted Workover Rig

-

The workover rigs are designed and manufactured in accordance with API Spec Q1, 4F, 7K, 8C and technical standards of RP500, GB3826.1, GB3836.2, GB7258, and SY5202.

-

The whole rig is compact, highly integrated, and requires a small space for installation.

-

Type 8x6 heavy-

duty chassis furnished with the rig carrier, complete with constant drive and self- propelled, equipped with hydraulic steering system and have a good capability of passage and cross country. -

A reasonable assembly of CAT engine and ALLISON transmission box can supply a high driving efficiency and increase safe performance.

-

Band brake or disc brake is applied for the main brake and the air disc brake/water brake or FDWS is used for auxiliary brake.

-

The compound box for rotary table has a function of forward-

reverse speed shift gears, which can be suitable for DP's rotary operations. The anti- torque releasing device can be used to release the deformation energy of the DP safely. -

The derrick is a two-

section, front open derrick can be telescoped, raised and extended hydraulically. -

The drill floor is twin-

body telescopic type or with parallelogram structure, which is convenient for installation and transportation. The dimension and height of the drill floor will be designed according to the user's requirements. -

Safety and inspection measures are strengthened to meet the requirements of HSE.

TAG£º

- ÉÏһƪ£ºTrailerized Desert AC Rig

- ÏÂһƪ£ºVFD Drive Systems